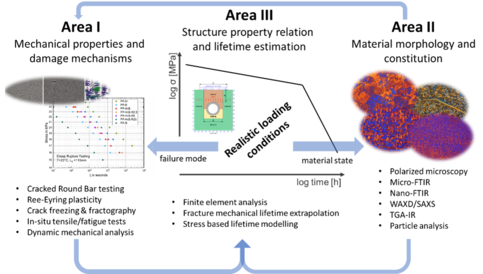

What are the possibilities and limits of using post-consumer recycled (PCR) polymers in polypropylene pipe applications? The team at the CD Laboratory for the Influence of Recycled Materials on the Mechanical Durability of Polymers is investigating this question. Three research areas are analysing which mechanical and morphological material properties and damage mechanisms have an influence on pipe materials and which intersections exist between structure and properties. The aim is to develop a method for estimating the service life under realistic load conditions.

Area 1

Mechanical properties and damage mechanisms

Area 1 will be split into sub areas, which will deal with the description and characterisation of the underlying damage mechanisms and subsequent long-term performance of PP, depending on the applied loading situation. While high applied loads will induce large scale plastic deformation and might even lead to buckling of the pipe, low loads induce a highly asymmetric load distribution around the pipe, which induces localized damage progression at the point of highest stresses/strains.

Area 2

Material morphology and constitution

The exact morphology, e.g. degree of crystallinity, sizes, shapes and distribution of spherulites, lamellar thicknesses, etc., of semi-crystalline polymers have a significant impact on the mechanical properties of a semi-crystalline material. Especially for long-term testing, where also physical ageing and annealing can occur during testing itself, this poses a significant challenge with regards to prediction of the final performance. The main goal of Area 2 will be to shed more light on this still rather veiled topic.

Area 3

Structure-property correlation and lifetime estimation

Once the underlying damage mechanisms and the impact of morphology and impurities are understood, the next step towards realistic and accurate lifetime estimation of materials containing PCR can be taken. However, the exact loading of buried non-pressure pipes is highly versatile. The main load stems from the pressure of the surrounding soil, which depends heavily on the used soil material, compaction, burying depth, trench surface, ground water level and estimated loading on top due to gravity and traffic. As the final failure depends on both material and loading situation, the results of this area will also bring vital information on the final lifetime of buried non-pressure pipes.