Each year, more than 1.5 million tonnes of steelmaking dust from electric arc furnaces are generated in the EU. This by-product, classified as hazardous waste, arises during the recycling of steel scrap; globally, annual volumes exceed 10 million tonnes. At present, these dusts are predominantly treated using the CO₂-intensive Waelz process to recover zinc. In addition to high emissions, large quantities of slag requiring landfill disposal are produced, resulting in the loss of valuable metals.

Project coordinator Dr. Manuel Leuchtenmüller explains: “Steelmaking dusts should not be seen as waste, but as a valuable resource that has so far been insufficiently utilized. With Dust2Value, we demonstrate that circular economy and climate protection can successfully go hand in hand.”

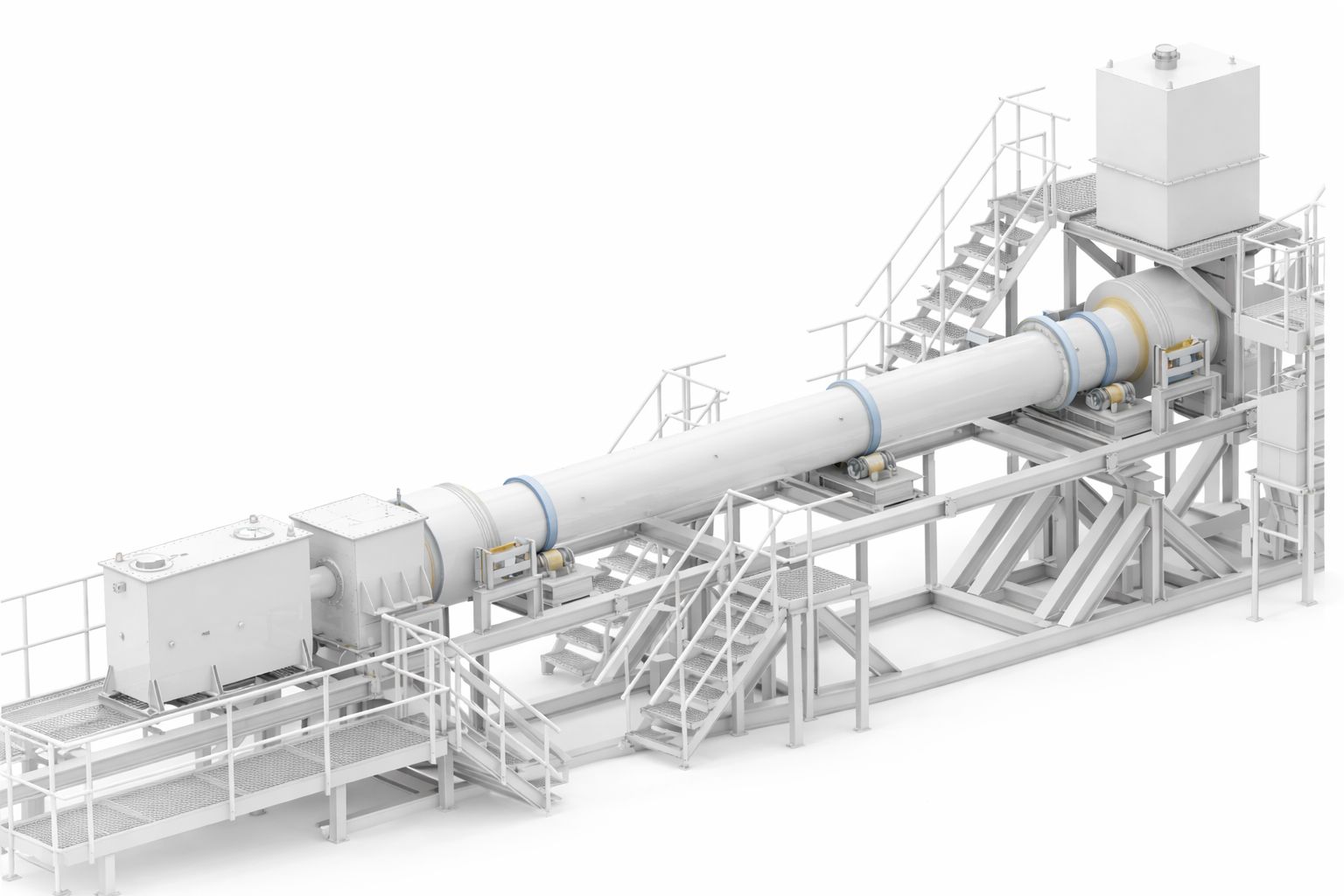

Novel Process Tested in a Demonstration Plant

The Dust2Value project directly addresses these challenges by developing an innovative process that replaces fossil carbon sources (coal and coke) with hydrogen. At the core of the technology is an innovative rotary kiln. A key feature of the new process is a closed hydrogen loop that regenerates the hydrogen required for zinc oxide reduction directly within the system, significantly reducing hydrogen consumption. Combined with the recovery of process heat, this results in a system that enables substantial CO₂ savings while delivering high-quality secondary raw materials.

The new process concept also avoids the formation of slag by producing so-called “sponge iron” in addition to zinc recovery. This material can be returned to the steel industry, not only conserving landfill capacity but also strengthening Europe’s strategic supply of critical industrial metals. Dust2Value thus opens up the prospect of a Europe-wide value chain for secondary raw materials, combining economic benefits with genuine sustainability.

In the first phase of the project, the scientific and technical foundations for future industrial implementation were already established. The project team investigated a wide range of steelmaking dusts across the EU and, in addition to detailed chemical and mineralogical analyses, conducted extensive reduction tests. This provided a representative picture of the actual material diversity and its behaviour in the future industrial process. In parallel, the complete technical design of the demonstration plant was finalized and is currently under construction.

Simulations and Digital Twin Validate the Plant Concept

Simulations assessing structural and thermal integrity confirm the safety and functionality of the plant concept, allowing construction of the pilot plant to proceed on a validated technical basis.

Another important milestone is the development of a digital twin. For the first time, real reaction rates were measured in laboratory experiments and are now being used as the basis for a precise simulation model. This makes it possible to predict how zinc extraction rates and iron metallization change as a function of the process input parameters—an essential prerequisite for stable and energy-efficient control of the future industrial process.

The results clearly exceed the current state of the art. The fully sealed, hydrogen-based process, which regenerates hydrogen within the system itself, enables particularly resource- and energy-efficient as well as sustainable operation. Model calculations indicate that the energy demand for zinc recovery can be reduced by around one third, while hydrogen consumption can be lowered by up to 90 percent.

Manuel Leuchtenmüller comments: “Real progress in climate protection must not depend on when low-cost hydrogen becomes available. That is why, from the very beginning, we focused on a closed-loop concept that regenerates hydrogen directly within the process.”

To enable the application of this novel process at an industrial scale, further steps are now planned. Process reliability must be demonstrated at larger scale using representative residual materials. The digital twin will be integrated into the plant control system to enable intelligent and efficient process regulation. At the same time, new marketing pathways for the recycled zinc and the iron-bearing sponge material will be developed. Establishing appropriate political and regulatory framework conditions for the safe industrial deployment of hydrogen-based recycling processes will also play a crucial role.

Project Information:

Project-Website: https://dust2value.eu/

LinkedIn: https://www.linkedin.com/company/dust2value

Project Coordinator:

Dr.mont. Manuel Leuchtenmüller

Montanuniversität Leoben

Lehrstuhl für Nichteisenmetallurgie

E-Mail: manuel.leuchtenmueller(at)unileoben.ac.at

Tel.: +43 3842 402-5258

Mobil: +43 664 80898 5258

Other participating organisational units at Montanuniversität Leoben: Chair of Ferrous Metallurgy, Chair of Nonferrous Metallurgy and Research and Innovation Service

Other project partners:

BEFESA R&D, S.L.U. (Spanien)

M.A.L. Metallbau Anlagenservice-Leitungsbau GmbH (Österreich)

POLITECNICO DI MILANO (Italien)

Georgsmarienhütte GmbH (Deutschland)

INSPYRO NV (Belgien)

BEFESA Steel Services GmbH (Deutschland)