Methane pyrolysis in a liquid metal bath

What is being researched?

CH4 is split into its components hydrogen and solid carbon. A major advantage of methane pyrolysis for hydrogen production is the significantly lower amount of energy required compared to electrolysis. This energy can be provided from renewable sources, resulting in a very small CO2 footprint. In addition to methane, biogas can also be used, which means that there are no more CO2 emissions.

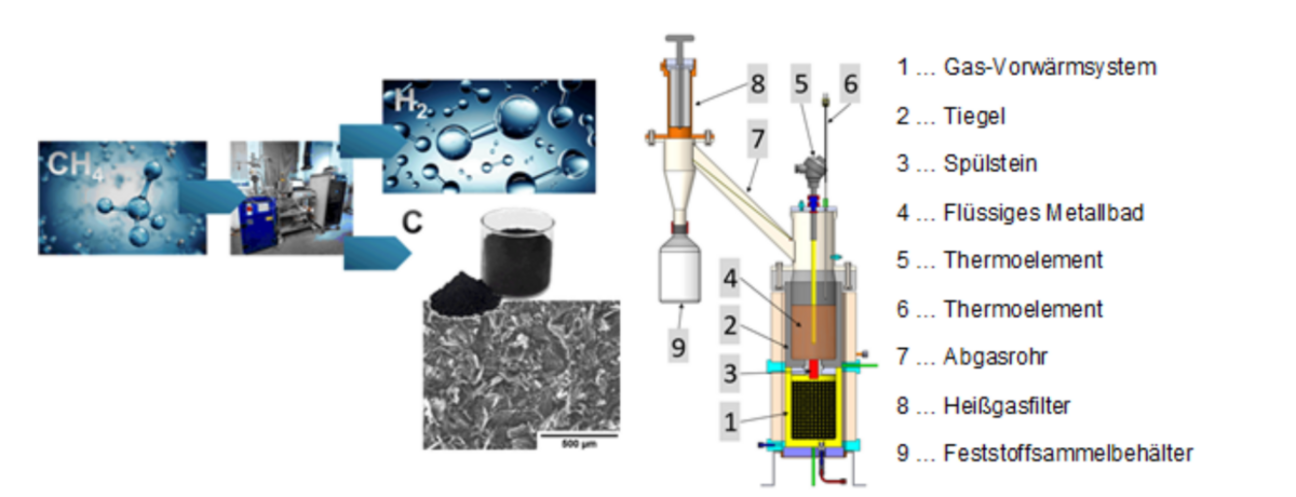

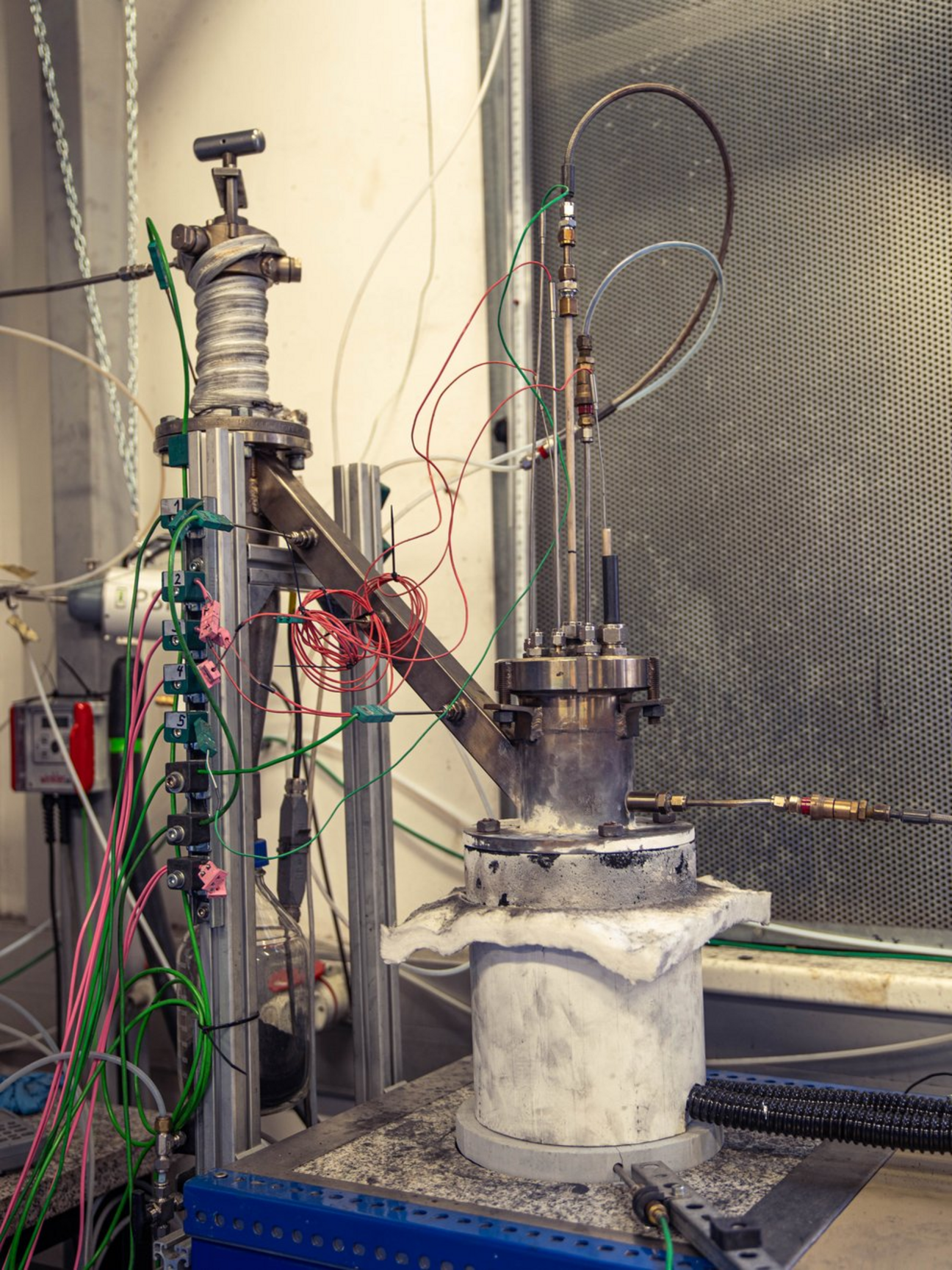

A team at the Chair of Nonferrous Metallurgy is working on the decomposition of methane and biogas by introducing it into a catalytic metal bath. In this context, the research and development of efficient liquid metal catalysts, which consist of different metal alloy systems, is of essential importance. With regard to the experimental setup, continuous further development and scaling of the existing systems is required (see figure). The optimization of the gas introduction system and the solids separation devices as well as the product gas treatment are important sub-areas. Based on this preliminary work on a laboratory scale, a large-scale methane pyrolysis laboratory will be set up in which various pyrolysis technologies and complete product gas processing for the recovery of carbon and hydrogen of varying purity can be investigated experimentally in collaboration with other departments.

Illustration of the principle of methane pyrolysis in a liquid metal bath and the laboratory-scale test facility (schematic)

What are the goals?

Decarbonization is to be achieved through the increased use of renewable energies, the use of which also conserves natural resources. One of the most promising strategies involves the use of hydrogen from methane pyrolysis (or biogas) as an energy source in industries that are difficult to decarbonize, such as steel production or the transport sector.

At present, however, an energy supply based on renewable hydrogen is not competitive compared to fossil hydrogen without CO2 capture (steam reforming) due to high costs. This is set to change in the coming years thanks to intensive research activities in the field of new or improved existing technologies and processes. The decomposition of natural gas or methane, but also biogas, therefore plays a central role as a transitional technology. The resulting hydrogen and carbon are high-quality products that are used in various industrial applications. In recent years, the use of molten metals as potential catalysts for methane pyrolysis has become increasingly important. Compared to conventional metal and carbon-based solid catalysts, these offer the advantage of far better heat transfer and high resistance to contamination-induced deactivation.

According to the literature, however, there is still no process scheme for methane pyrolysis in a metal bath that could be used on a larger scale, or there are usually only ideas (no test set-up). The aim of the project is therefore to develop a pyrolysis technology for methane and

natural gas and subsequently also for solid and liquid hydrocarbons with regard to suitable metal catalysts and the process engineering design, which also enables feasible upscaling.

About Dipl.-Ing. Dr.mont. Stefan Wibner

I studied metallurgy at the University of Leoben and completed my doctorate at the Chair of Non-ferrous Metallurgy in the field of aluminum recycling. Already at the HTL Bulme in Graz-Gösting for machine and plant engineering, I was particularly interested in welding, casting and forging technology and in the production of metals (which was only covered to a limited extent there, however). I therefore decided to study metallurgy, where these topics are dealt with in great detail. I was particularly enthusiastic about the scientific principles and the sustainable approach to metal production processes and the recycling of various residual materials. At the Chair of Nonferrous Metallurgy, I am involved in a wide variety of research projects in the field of recycling metal-containing residues and now, in particular, the topic of methane pyrolysis in the liquid metal reactor. This technology is particularly interesting, as hydrogen production is currently gaining in importance and will continue to do so in the future, and methane pyrolysis is a key technology in this context, producing not only H2 but also solid carbon, which is considered a critical raw material. For the future, I hope that new, more environmentally friendly processes and procedures can be used and established more quickly and effectively and that the political/social/bureaucratic barriers will fall. Innovative research should bring social benefits and make work easier, whereby environmentally relevant effects must be taken into account and given priority.

Other project employees - Methane pyrolysis:

Dipl.-Ing, David Neuschitzer

Dipl.-Ing David Scheiblehner

Ing. Andreas Sprung