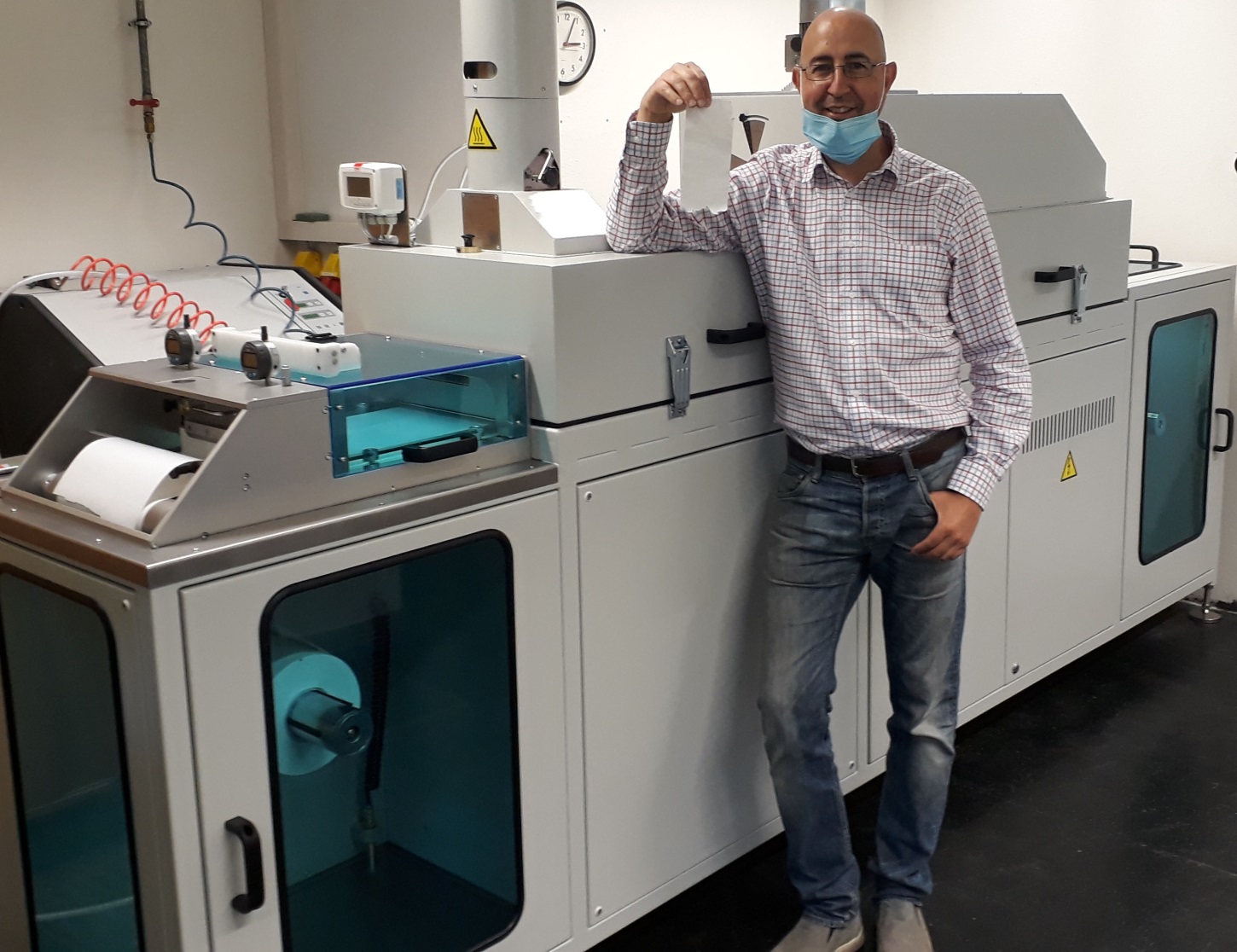

Recent work at the Chair of Structural and Functional Ceramics (ISFK) deals with the design and fabrication of laminates or multilayer components as they are used in microelectronics. In laminates, internal stresses can be adjusted by combining layers of different materials in such a way that cracks originating from the surface are stopped just below the surface. This can guarantee a minimum value for the bending strength of the laminate, which can be very high (several hundred MPa). The laminate behaves as if it had many times the fracture toughness of its individual layer materials. In this field, it is intended to start the development and fabrication of bio-inspired structures with high reliability. Therefore, a laboratory is currently being set up in which the internal structure of ceramic components can be adjusted by means of tape casting in such a way that structural and functional properties can be specifically improved. A tape caster was installed in May, and the first foils (with a thickness of approx. 50µm) were already drawn.